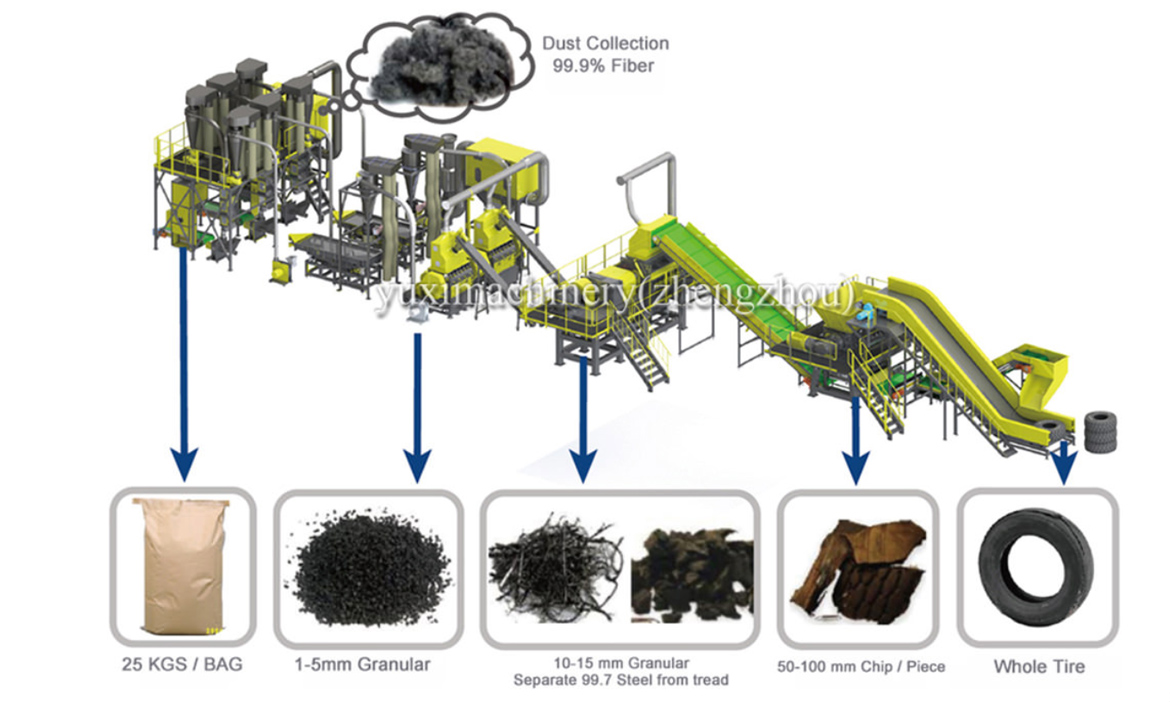

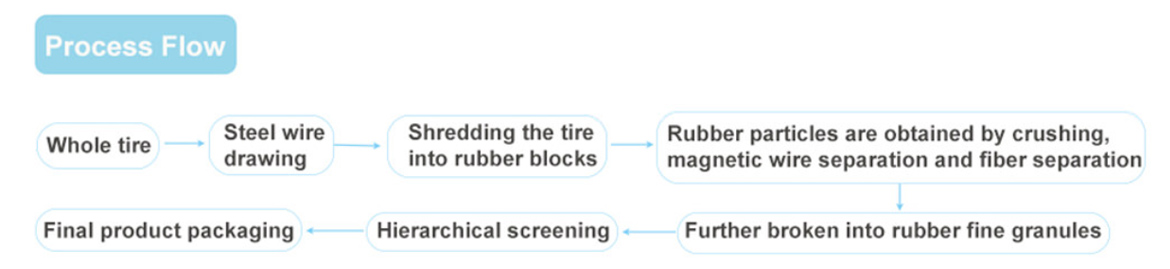

♦ The double shaft tire shredding machine preprocesses the entire tire into approximately 50-80 mm rubber crumb.

2.Steel Wires Separate Machine

♦ The tire chips were further processed into less than 20mm by serrated knife of steel wires separate machine.

96% of the steel wires had been separated from the tire during this step of treatment.

3.Magnetic Separator

♦ The electromagnetic coils will be made from high temperature resistant insulates aluminum and copper conductor for continuous operation.

The magnetic metal removal rate reaches 99.7%

4.High-speed Crusher

♦The crusher further processes the tire rubber particles into 2-7mm particles.the nylon and the fiber are removed 99.6% by a dust remover.

5.Vibrating Screening Machine

♦ The broken material is divided into upper sieve and under sieve by the standard 3 mm hole diameter to ensure the purity of the subsequent sorting process.

6.Dust Collection of Tire Recycling Machine Line

Waste Tire Shredder

Waste Tire Shredder Scrap Metal Shredder

Scrap Metal Shredder Scrap Metal Crushing Plant

Scrap Metal Crushing Plant Crocodile Shear

Crocodile Shear Scrap Metal Baler Machine

Scrap Metal Baler Machine AC Radiator Recycling Line

AC Radiator Recycling Line Scrap Car Crushing Separating Line

Scrap Car Crushing Separating Line Scrap Car Crushing Line

Scrap Car Crushing Line